MORE MISSION FURNITURE PLANS

MAKE MONEY FLIPPING FURNITURE

If you’re looking for a home business that can return you a profit in as little as 24 hours, then ‘flipping furniture for profit’ will shock you!

REVIEW OF TED'S WOOD-

WORKING

WOOD WORKING FOR BEGINNERS

|

A BLACKING CASE TABOURET

A substantial piece of mission furniture which may

be used as a tabouret (stool) or plant stand as well as a

blacking case, in which there is a receptacle for

brushes, blacking [NOTE: blacking means shoe shine polish] and a shoe rest, is shown in the

illustration. The stock can be secured mill-planed,

sandpapered and in lengths almost ready to be assembled.

The stock list consists of the following pieces:

- 4 posts, 1-1/2 by 1-1/2 by 17 in.

- 4 side rails, 1 by 6-1/2 by 9-1/2 in.

- 2 top pieces, 1 by 8-1/4 by 16-1/2 in.

- 1 bottom, 1/4 by 9-1/2 by 9-1/2 in.

- 1 cleat, 1 by 1 by 18 in.

The posts and cleat are surfaced on four sides, while the other pieces

are surfaced on only two sides. The allowance of 1/2 in. on the

side rails, top and bottom, is for fitting the joints. Be sure the

surfaces of the pieces for the posts are square and the ends sawed

square off, making the posts exactly the same length when they come from

the mill.

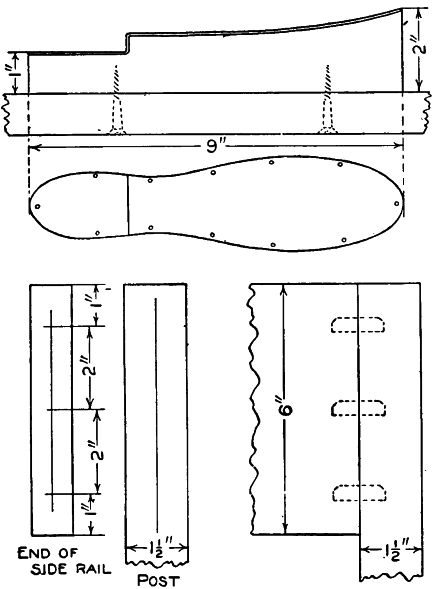

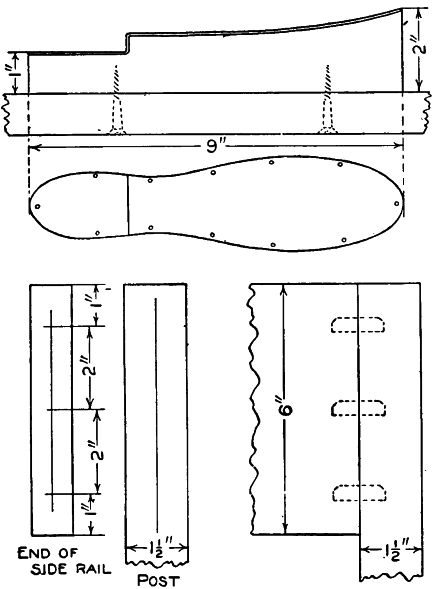

Details of Shoe Rest

Details of Shoe Rest

Square up the four side rails to 6 by 9 in. Cut one end of each post

tapering with a chisel; face and sandpaper the posts and side rails

before making the joints. The side rails are attached to the posts with

three dowels to each joint. The place for each dowel is located by

making a line exactly in the middle lengthwise on each end of each side

rail. Three lines are made to intersect this middle line, as shown in

the detail. Drive a 1/2-in. brad in each intersection allowing a small

portion of each brad to project, and cut off the heads. Gauge a line in the middle of each post at the top where the

joints are to be made and press the end of a side rail containing the

brads against the post. This will mark the places to bore holes for the

dowels. Pull out the brads and bore holes for the dowel pins.

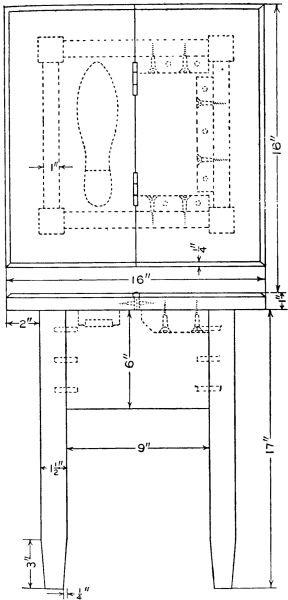

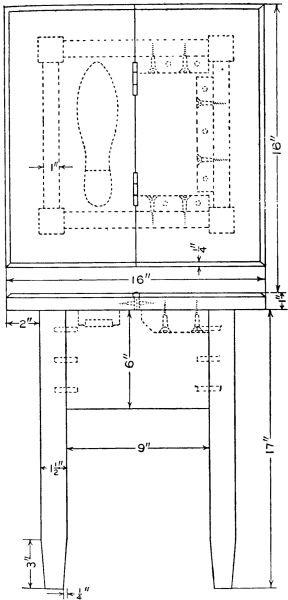

Details of Tabouret Construction

Details of Tabouret Construction

When gluing up the side rails and posts, first put on a coat of glue on

the ends of the side rails and let it dry. This will fill up the pores

in the end grain of the wood which will

make a strong joint when finally glued together. The dowel pins are made 3/8 in.

square with a slight taper at the ends. These can be easily forced into

the holes, when the ends of the side rails are coated with glue and

ready to be put together, by clamps pressing on the outside of the

posts.

The bottom is held in position with narrow strips tacked on the lower edge of the side rails. Square up the top pieces to 8 by 16 in. and

fasten one piece to the top with cleats and screws as shown in the drawing. The other piece is hinged to the first one with two 2-in.

hinges. The bottom is held in position with narrow strips tacked on the lower edge of the side rails. Square up the top pieces to 8 by 16 in. and

fasten one piece to the top with cleats and screws as shown in the drawing. The other piece is hinged to the first one with two 2-in.

hinges.

The shoe rest can be made from a block of wood and covered with sheet tin, copper or brass, or a cast-iron rest can be purchased. The rest is

fastened to the under side of the hinged top. Stain the wood any dark color and apply a very thin coat of shellac. Put on wax and you will

have a finish that can be renewed at any time by wiping with a little turpentine and rewaxing.

|

Details of Shoe Rest

Details of Shoe Rest

Details of Tabouret Construction

Details of Tabouret Construction