MORE MISSION FURNITURE PLANS

MAKE MONEY FLIPPING FURNITURE

If you’re looking for a home business that can return you a profit in as little as 24 hours, then ‘flipping furniture for profit’ will shock you!

REVIEW OF TED'S WOOD-

WORKING

WOOD WORKING FOR BEGINNERS

|

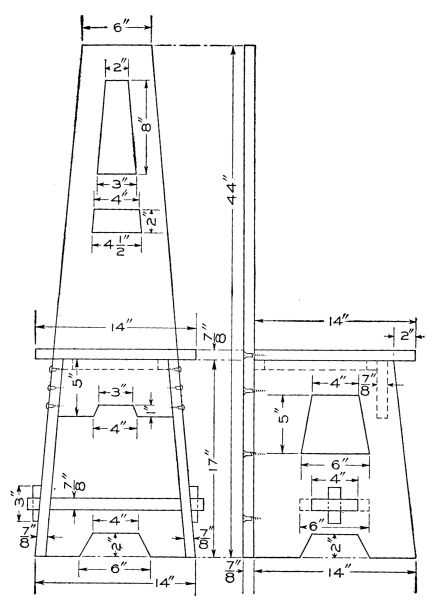

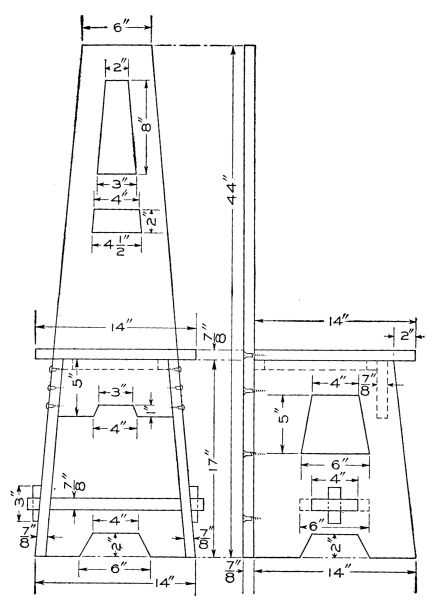

A MISSION HALL CHAIR

This hall chair is designed to take up as little room as possible. For its construction the following stock will be needed:

- 1 back, 7/8 by 14 by 44 in., S-2-S.

- 2 sides, 7/8 by 14 by 17 in., S-2-S.

- 1 seat, 7/8 by 14 by 14 in., S-2-S.

- 1 stretcher, 7/8 by 6 by 16 in., S-2-S.

- 1 brace, 7/8 by 5 by 11 in., S-2-S.

- 1 piece, 7/8 by 7/8 by 44 in., for cleats.

These dimensions are for finished pieces, therefore 1/4 in. should be allowed for planing if the stock cannot be secured finished.

Making Furniture at Home - Chair Making - Making the Mission Hall Chair

Lay out and cut the design on the back, sides, and brace. To cut the openings, first bore a hole near one corner to get the blade of a coping

saw through and proceed to saw to the lines. Smooth the edges after sawing by taking a thin shaving with a sharp chisel. A file will not

leave a good surface.

Mark the tenons on the ends of the stretcher and cut them with a backsaw and make smooth with a chisel. From the tenons mark the mortises in the

sides through which they are to pass.

Detail of the Hall Chair

Detail of the Hall Chair

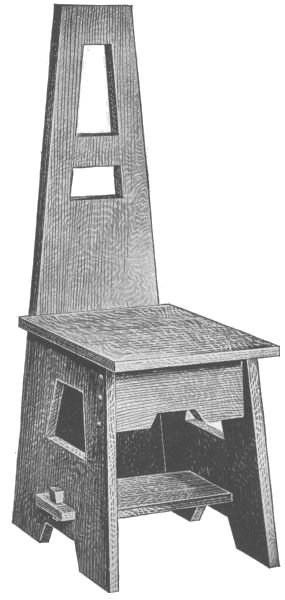

Complete Hall Chair in Plain Oak

Complete Hall Chair in Plain Oak

To cut these mortises, first bore a row of holes with a 5/8 in. bit, boring halfway from each side so as not to split off any pieces. Now

make of scrap material the two keys and from them mark the small mortises in the tenons.

Before putting the chair together, the cleats for holding the seat should be fastened to the sides, back and brace. Use flat-head screws

for this purpose. Then put the sides and stretcher together, and fasten the back to the sides with flat-head screws.

The brace should be put in next, using three round-head screws in each end. There only remains the top, which is held by screws through the cleats from the under side.

Stain with two coats of weathered or mission-oak stain, and then apply a thin coat of "under-lac" or shellac and two coats of wax.

|

Detail of the Hall Chair

Detail of the Hall Chair

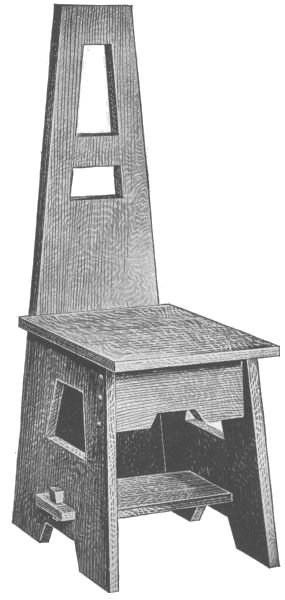

Complete Hall Chair in Plain Oak

Complete Hall Chair in Plain Oak