For the top, order 1 piece 1-1/8 in. thick, 34 in. wide and 46 in. long.

Have it S-4-S (surface on four sides) and "squared" to length. Also

specify that it be sandpapered on the top surface, the edges and ends.

For the shelf, order 1 piece 7/8 in. thick, 22 in. wide and 42 in. long,

with the four sides surfaced, squared and sandpapered the same as for

the top.

For the side rails, order 2 pieces 7/8 in. thick, 6 in. wide and 37 in.

long, S-4-S and sanded on one side. For the end rails, 2 pieces 7/8 in.

thick, 6 in. wide and 25 in. long. Other specifications as for the side

rails.

For the stretchers, into which the shelf tenons enter, 2 pieces 1-1/8

in. thick, 3-3/4 in. wide and 25 in. long, surfaced and sanded on four

sides. For the slats, 10 pieces 5/8 in. thick, 1-1/2 in. wide and 17 in.

long, surfaced and sanded on four sides. For the keys, 4 pieces 3/4 in.

thick, 1-1/4 in. wide and 2-7/8 in. long, S-4-S. This width is a little

wide; it will allow the key to be shaped as desired.

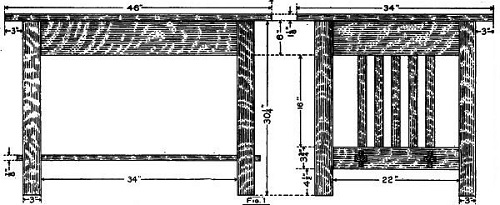

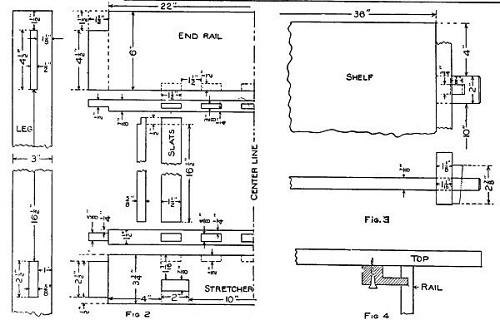

The drawings obviate any necessity for going into detail in the

description. Fig. 1 gives an assembly drawing showing the relation of

the parts. Fig. 2 gives the detail of an end. The tenons for the side

rails are laid off and the mortises placed in the post as are those on

the end. Care must be taken, however, not to cut any mortises on the

post below, as was done in cutting the stretcher mortises on the ends of

the table. A good plan is to set the posts upright in the positions they

are to occupy relative to one another and mark with pencil the

approximate positions of the mortises. The legs can then be laid flat and the mortises accurately marked out with a fair degree of

assurance that they will not be cut where they are not wanted and that the

legs shall "pair" properly when effort is made to assemble the parts of the table.

The table ends should be glued up first and the glue allowed to harden,

after which the tenons of the shelf may be inserted and the side rails

placed.

There is a reason for the shape, size and location of each tenon or

mortise. For illustration, the shape of the tenon on the top rails

permits the surface of the rail to extend almost flush with the surface

of the post at the same time permitting the mortise in the post to be

kept away from that surface. Again, the shape of the ends of the slats

is such that, though they may vary slightly in length, the fitting of

the joints will not be affected. Care must be taken in cutting the

mortises to keep their sides clean and sharp and to size.

In making the mortises for the keyed tenons, the length of mortise must

be slightly in excess of the width of the tenon - about 1/8 in. of

play to each side of each tenon. With a shelf of the width specified for

this table, if such allowance is not made so that the tenons may move

sideways, the shrinkage would split the shelf.

In cutting across the ends of the shelf, between the tenons, leave a

hole in the waste so that the turning saw or compass saw can be

inserted. Saw within one-sixteenth of the line, after which this margin

may be removed with chisel and mallet.

In Fig. 3 is shown two views of the keyed tenon and the key. The mortise

for the key is to be placed in the middle of the tenon. It will be noted

that this mortise is laid out 1-1/16 in. from the shoulder of the

tenon while the stretcher is 1-1/8 in. thick. This is to insure the

key's pulling the shelf tightly against the side of the stretcher.

Keys may be made in a variety of shapes. The one shown is simple and

structurally good. Whatever shape is used, the important thing to keep

in mind is that the size of the key and the slant of its forward surface

where it passes through the tenon must be kept the same as the mortise

made for it in the tenon.

The top is to be fastened to the rails by means either of wooden

buttons, Fig. 4, or small angle irons.

There are a bewildering number of mission finishes upon the market. A

very satisfactory one is obtained by applying a coat of brown Flemish

water stain, diluted by the addition of water in the proportion of two

parts water to 1 part stain. When this has dried, sand with No. 00

paper, being careful not to "cut through." Next, apply a coat of dark

brown filler; the directions for doing this will be found upon the can

in which the filler is bought. One coat usually suffices. However, if an

especially smooth surface is desired, a second coat may be applied in a

similar manner.

Once the filler has hardened, put on a very thin coat of shellac. When the shellac has dried, it should be sanded lightly and then one or two coats of wax should be applied and polished. Directions for waxing are on the cans in which the wax is bought. A beautiful dull gloss so much sought by finishers of modern furniture will be the result of carefully following these directions.

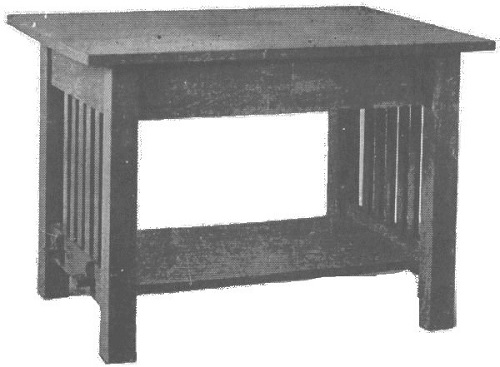

This Picture is from a Photograph of the Mission Table Described in This Article

This Picture is from a Photograph of the Mission Table Described in This Article

Details of Table Construction

Details of Table Construction