MORE MISSION FURNITURE PLANS

MAKE MONEY FLIPPING FURNITURE

If you’re looking for a home business that can return you a profit in as little as 24 hours, then ‘flipping furniture for profit’ will shock you!

REVIEW OF TED'S WOOD-

WORKING

WOOD WORKING FOR BEGINNERS

|

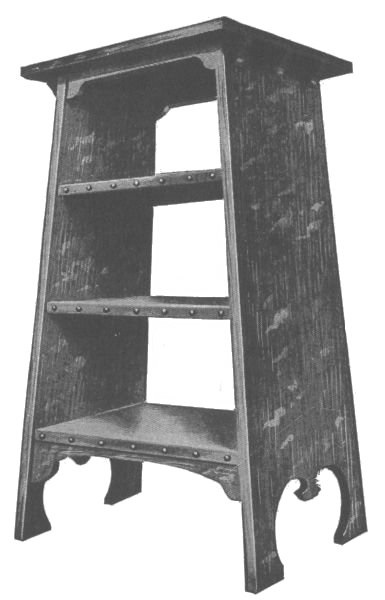

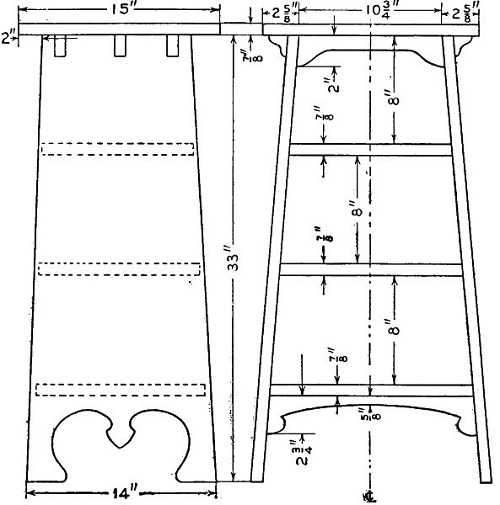

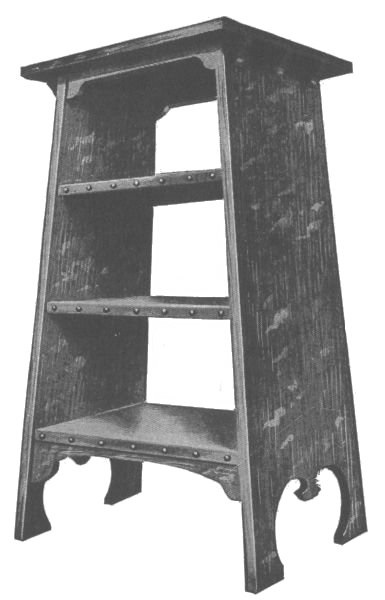

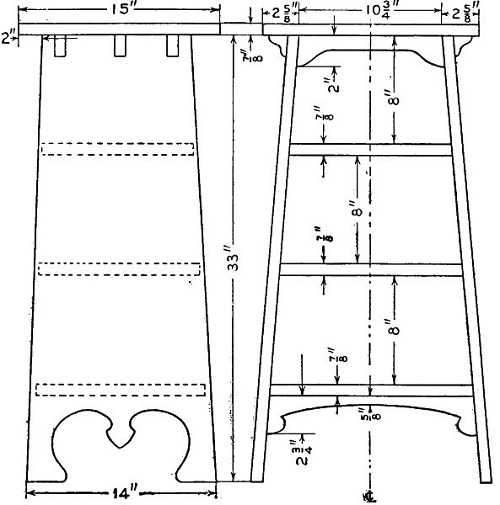

HOW TO MAKE AND FINISH A MAGAZINE STAND

For the magazine stand shown herewith there

will be needed the following pieces:

- 1 top, 7/8 in. by 15-1/2 in. by 16-1/2 in.

- 1 shelf, 7/8 in. by 11-1/2 in. by 12-1/2 in.

- 1 shelf, 7/8 in. by 12-1/2 in. by 14-3/4 in.

- 1 shelf, 7/8 in. by 13-1/2 in. by 16-1/2 in.

- 2 sides, 7/8 in. by 14-1/2 in. by 33-1/2 in.

- 1 brace, 7/8 in. by 3-1/4 in. by 17 in.

- 1 brace, 7/8 in. by 2-1/2 in. by 11-1/2 in.

- 6 braces, 7/8 in. by 2 in. by 2 in.

Order these pieces mill-planed on two surfaces to the thickness specified above and also sandpapered.

Quarter-sawed white oak makes the best appearance of all the woods that are comparatively

easy to obtain. Plain sawed red or white oak will look well but are more liable to warp than the

quarter-sawed. This is quite an element in pieces as wide as these.

Begin work on the sides first. Plane a joint edge on each and from this work the two ends. The ends

will be square to the joint edge but beveled to the working face. A bevel square will be needed for

testing these beveled ends.

To set the bevel make a drawing, full size or nearly so, of the front view and place the bevel on the drawing,

adjusting its sides to the angle wanted. Work from a center line in laying off the drawing.

Having planed the ends, lay off the sides. This is done by measuring from the joint edge along the

bottom 14 in., from the joint edge along the top 1-1/2 in. and from this 11 in. Connect the points by

means of a pencil and straightedge.

Completed Stand

Completed Stand

Before cutting off the joint edges of the pieces

measure off and square lines across to indicate the

locations of the shelves. Put both pieces together

and mark across both joint edges at once to insure

getting both laid off alike.

The design at the bottom can be varied to suit

the fancy of the worker. For such a design as is

shown, draw on paper, full size, half of it; fold on

the center line and with scissors cut both sides of

the outline by cutting along the line just drawn.

Trace around this pattern on the wood, and saw out

with compass or turning saw.

The shelves may now be made. The bevel of the

ends of the shelves will be the same as for the ends

of the side pieces. The lengths may be obtained by

measuring the drawing. Remember that length is

always measured along the grain and that the end

grain of the shelves must extend from side to side

in this stand. The widths may be obtained by measuring

the width of the sides at the points marked

out on them for the location of the shelf ends. It is

best not to have the shelves the full width of the

sides, since the edges of the shelves are to be faced

with leather. Make each shelf 1/2 in. less than the

width of the side, at the place that the shelf is to

be fastened.

The top will be squared up in the usual manner, 15 in. wide by 16 in.

long.

These parts may now be put together. They may be fastened in any one of

a variety of ways. Round-head blued screws may be placed at regular

intervals through the sides. Finishing nails may be used and the heads

set and covered with putty stained to match the wood. Finish nails may

be placed at regular intervals and fancy headed nails used to cover the

heads.

Details of the Magazine Stand

Details of the Magazine Stand

The braces should be formed and fitted but not

fastened until the finish has been applied. Thoroughly

scrape and sandpaper all parts not already

so treated. Probably no other finish appeals to so

many people as golden oak. There is no fixed standard

of color for golden oak. Different manufacturers

have set standards in their part of the country, but the prevailing idea of golden oak is usually that of a

rich reddish brown.

Proceed as follows: Egg shell gloss:

1.—One coat of golden oak water stain, diluted with water if a light golden is desired.

2.—Allow time to dry, then sandpaper lightly with fine sandpaper.

This is to smooth the grain and to bring up the high lights by removing

the stain from the wood. Use No. 00 sandpaper and hold it on the finger

tips.

3.—Apply a second coat of the stain diluted about one-half

with water. This will throw the grain into still higher relief and thus

produce a still greater contrast. Apply this coat of stain very

sparingly, using a rag. Should this stain raise the grain, again rub

lightly with fine worn sandpaper, just enough to smooth.

4.—When

this has dried, put on a light coat of thin shellac. Shellac precedes

filling that it may prevent the high lights—the solid parts of the

wood—from being discolored by the stain in the filler, and thus

causing a muddy effect. The shellac being thin does not interfere with

the filler's entering the pores of the open grain.

5.—Sand lightly with fine sandpaper.

6.—Fill with paste filler colored to match

the stain.

7.—Cover this with a coat of orange shellac. This coat

of shellac might be omitted, but another coat of varnish must be added.

8.—Sandpaper lightly.

9.—Apply two or three coats of

varnish.

10.—Rub the first coats with hair cloth or curled hair

and then with pulverized pumice stone, crude oil or linseed oil. Affix

the braces just after filling, using brads and puttying the holes with

putty colored to match the filler. The shelves may be faced with thin

leather harmonizing with the oak, ornamental headed tacks being used to

fasten it in place.

|

Completed Stand

Completed Stand

Details of the Magazine Stand

Details of the Magazine Stand