First make and put together the sides of the chair. While the glue is

setting on these parts make and assemble the back. The front and back

rails may next be made and placed and the cleats and bottom slats

fastened. With the adjustment of the back the chair is ready for the

finish.

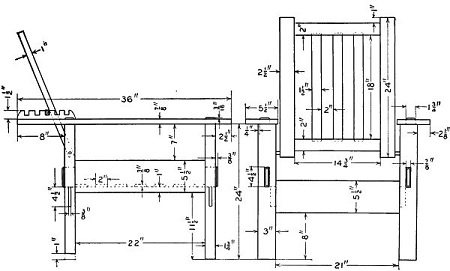

The posts are to be tenoned on the upper ends. These tenons are to

project 3/16 in. above the arm and should be slightly beveled. The lower

ends of the posts, likewise, all other projecting ends, should be

beveled to avoid their splintering. All sharp corners, as on the arms,

should be sandpapered just enough to take their sharpness off, so as not

to injure the hand.

That the chair may be properly inclined, the rear posts are cut 1 in.

shorter than the forward ones. To get the correct slant on the bottoms

of these posts, lay a straightedge so that its edge touches the bottom

of the front post at its front surface, but keep it 1 in. above

the bottom of the rear post. Mark with pencil along the straightedge

across both posts.

At the rear ends of the arms are the notched pieces that allow the back to be adjusted to different

angles. These pieces may be fastened in place either by means of roundhead screws from above or

flatheads from underneath the arms. The notches are to be cut 3/4 in. deep. If more than three adjustments

are wanted, the arms must be made correspondingly longer.

The dimensions for the tenons on all the larger pieces will be found on

the drawing. For the back, the tenons of the cross pieces, the rails,

should be 3/8 by 1-1/4-in. For the slats, the easiest way is to not

tenon them but to "let in" the whole end, making the mortises in the

rails 3/8 by 1-1/2 in. This will necessitate cutting the sides of the

mortises very accurately, but this extra care will be more than

compensated by not having to bother with the cutting of tenons on each

end of the three back slats.

To finish the chair, put on a coat of water stain, first removing all

surplus glue and thoroughly scraping and sandpapering all the parts that

were not so treated at the mill. The color of the stain will depend upon

the finish desired, whether golden, mission, etc. Water stains cause the

grain of the wood to roughen, so it will be necessary to resandpaper the

surfaces after the stain has dried, using fine paper. Next apply a coat

of filler colored to match the stain. Directions for its application

will be found upon the cans in which the filler comes. After the filler

has hardened put on a very thin coat of shellac.

What step is taken next will depend upon what kind of a surface is

desired. Several coats of polishing wax may be put on. This is easily

done—directions will be found on the cans—and makes the most

satisfactory finish for mission and craftsman furniture. It is the

easiest to apply. Several coats of shellac or of varnish might be put on

instead of wax. Each coat of the shellac should be rubbed when

thoroughly dried with curled hair or fine steel wool or fine oiled

sandpaper. Rub the first coats of varnish with hair-cloth or curled hair

and the last coats with pulverized pumice stone and crude oil or raw linseed oil.

Cushions for the chair can be made at home. They may be made of art

leather such as Spanish roan skin and the top and bottom parts fastened

together by lacing leather thongs through holes previously punched along

the edges of the parts. A very pretty effect is obtained by using thongs

of a different but harmonious color. The manner of lacing may be any one

of the various laces such as are used in lacing belts or as shoestrings.

These cushions may be filled with hair or cotton felt. Denim or burlap

may also be used as a covering and are much less expensive than the

leather. Lace one side and the two ends, then place filling and finish lacing.

Art leather cushions retail at from $16 to $20 a pair and the denim and burlap at $6 to $9.

The bottom cushion should be made the full size of the chair. The front and back rails extend a little above the slats and thus hold it in

place. The back cushion will settle down a little and therefore may be made nearly the full length from the slats to the top of the back.

Complete Morris Chair Without Cushion

Complete Morris Chair Without Cushion  Details of a Morris Chair

Details of a Morris Chair