MORE MISSION FURNITURE PLANS

MAKE MONEY FLIPPING FURNITURE

If you’re looking for a home business that can return you a profit in as little as 24 hours, then ‘flipping furniture for profit’ will shock you!

REVIEW OF TED'S WOOD-

WORKING

WOOD WORKING FOR BEGINNERS

|

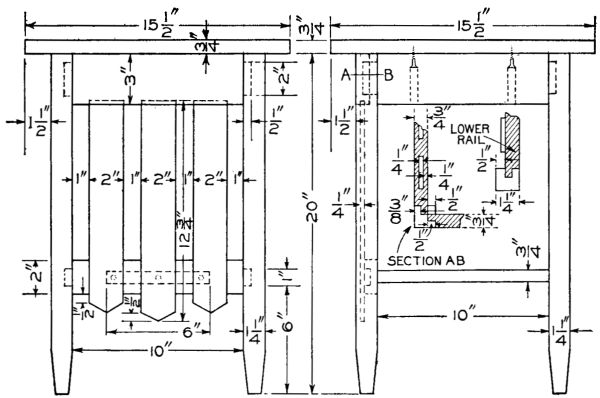

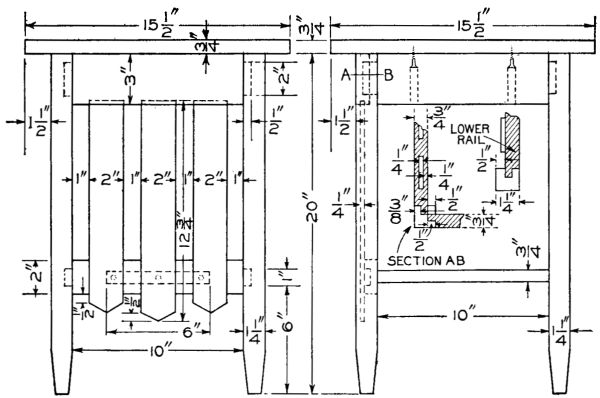

A MISSION PLANT STAND

For the mission plant stand shown in the illustration

secure the following list of quarter-sawed

white-oak stock, cut and finished to size:

- 1 top, 3/4 by 15-1/2 by 15-1/2 in., S-2-S.

- 4 posts, 1-1/4 by 1-1/4 by 20 in., S-4-S.

- 4 rails, 3/4 by 3 by 11 in., S-2-S.

- 2 rails, 3/4 by 2 by 11 in., S-2-S.

- 1 shelf, 3/4 by 6 by 10 in., S-2-S.

- 4 slats, 1/4 by 2 by 12-1/4 in., S-2-S.

- 2 slats, 1/4 by 2 by 12-3/4 in., S-2-S.

Test all surfaces of the posts with a try-square to see that they are

square with each other. Lay out the tenons on the ends of the rails as

shown in the sketch and cut with a tenon saw and chisel. Arrange the posts and rails as they are to

stand and number each tenon and mortise. Lay out the mortises in the

legs, taking the measurements directly from the tenon which is to fit

that mortise. Cut the mortises, first having bored to the depth with a

1/4-in. bit.

Detail of the Plant Stand

Detail of the Plant Stand

The slats should now be made and mortised into

the top rail 1/4 in. They come outside of the lower

rail and are held to it with two small brads, fancy-headed

tacks, or round-head screws.

In laying out the mortises for the lower rails,

care must be taken to have them set 1/8 in. farther

in than the upper rails so the slats may come

outside.

Set up the stand without glue or screws to see

that all pieces fit accurately. Then glue up the sides with the slats first. After these have set for 24

hours, fit in the other two rails and the shelf. Three

flat-head screws should be used to hold the shelf

in place. These must be placed so the slats will

cover them when they are attached.

Complete Plant Stand

Complete Plant Stand

When this work is completed it is ready for the top. A good method of

attaching the top is shown in the sketch. The screws used for fastening

should be 2-in. No. 10. Bore into the rail 1-1/2 in. with a bit 1/16 in.

larger than the head of the screw. Then bore through the rest of the way

with a bit a little larger than the shank of the screw. Thus a

little space is left for expansion and shrinkage of the top.

Scrape and sandpaper thoroughly to remove all marks or glue spots.

Finish with two coats of weathered-oak stain, followed by two coats of

black wax.

|

Detail of the Plant Stand

Detail of the Plant Stand