MISSION FURNITURE

REVIEW OF TED'S WOOD-

WORKING

WOOD WORKING FOR BEGINNERS

|

A MISSION SIDEBOARD

Oak is the most suitable material for making this sideboard and it should be first-class stock, planed and cut to the dimensions given in the following list:

- 1 top, 7/8 by 22 by 48 in., S-2-S.

- 1 top shelf, 7/8 by 12 by 48 in., S-2-S.

- 1 bottom, 7/8 by 22 by 48 in., S-2-S.

- 2 back posts, 2 by 2 by 57 in., S-4-S.

- 2 front posts, 2 by 2 by 36 in., S-4-S.

- 2 standards, 2 by 2 by 20 in., S-4-S.

- 2 mirror rails, 7/8 by 2 by 47 in., S-2-S.

- 2 mirror rails, 7/8 by 2 by 20 in., S-2-S.

- 3 front and back rails, 7/8 by 3 by 46 in., S-2-S.

- 4 end rails, 7/8 by 3 by 20 in., S-2-S.

- 4 standard rails, 7/8 by 2 by 10 in., S-2-S.

- 2 vertical pieces, 7/8 by 19-1/2 by 22 in., S-2-S.

- 1 horizontal piece, 7/8 by 22 by 14-1/4 in., S-2-S.

- 1 drawer front, 7/8 by 6 by 14-1/4 in., S-2-S.

- 1 piece, 7/8 by 3 by 3 in.

- 4 vertical door pieces, 7/8 by 2 by 17 in., S-2-S.

- 4 horizontal door pieces, 7/8 by 2 by 15 in., S-2-S.

- 2 drawer sides, 7/8 by 5 by 14 in., S-2-S.

- 1 drawer bottom, 1/4 by 14 by 14-1/4 in., S-2-S.

- 1 back panel, 1/4 by 16-1/2 by 44-1/2 in., S-2-S.

- 2 door panels, 1/4 by 10-1/2 by 15-1/2 in., S-2-S.

- 2 side panels, 1/4 by 18-1/2 by 16-1/2 in., S-2-S.

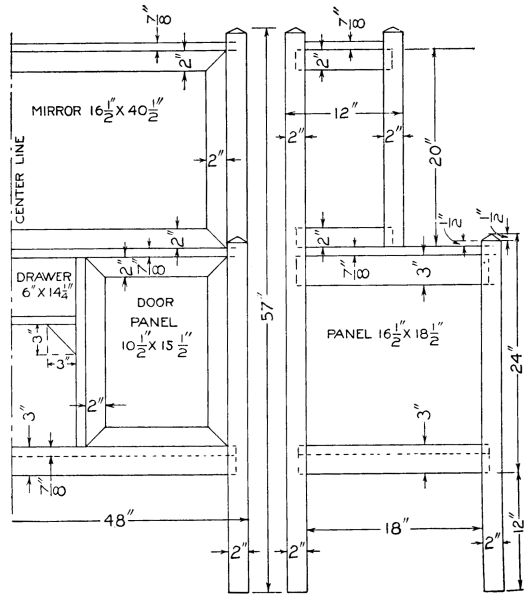

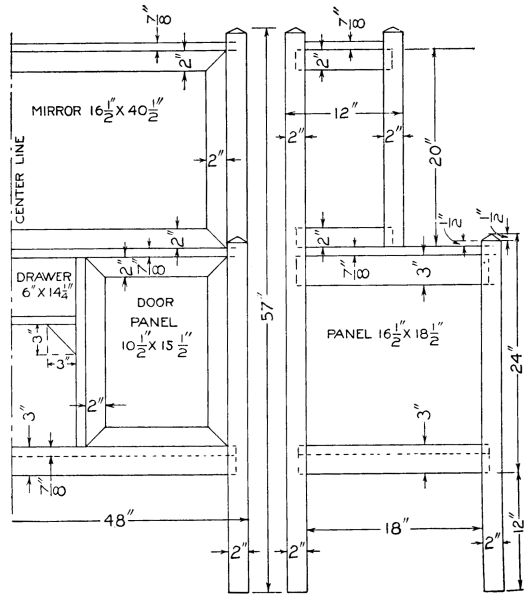

Detail of the Mission Sideboard

Detail of the Mission Sideboard

Begin work by cutting the posts to the length indicated in the detail

drawing. The top ends are tapered with a 1/2-in. slant. These posts are

cut in pairs and it is best to stand them up in the same[105] position they will be in the

finished sideboard, and mark the sides to be mortised with a pencil.

Also cut the grooves into which the panels are to fit. These are to be

1/4 in. wide and a little over 1/4 in. deep.

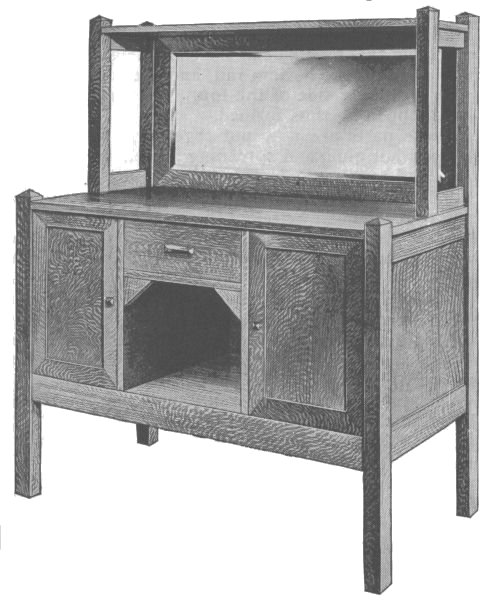

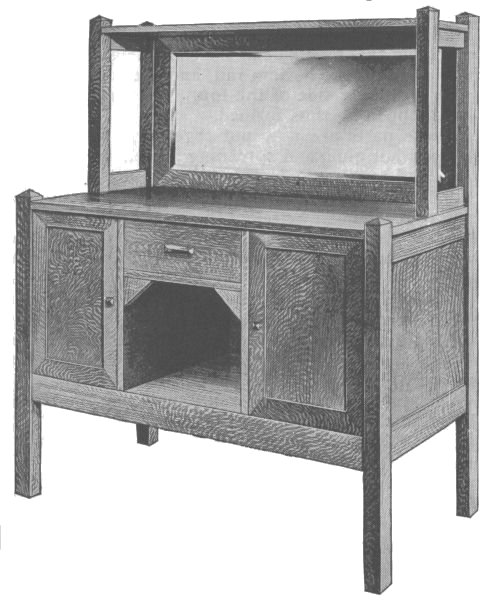

Mission Sideboard in Quarter-Sawed Oak

Mission Sideboard in Quarter-Sawed Oak

[106]

The rails are cut with tenon ends to match the mortises, and also have

grooves to receive the panels.

The bottom part of the back is closed with a panel and two rails, one at

the same height from the floor as the front bottom rail, and the top one

even with the under side of the top. The large panel is for the opening

thus formed.

These parts are now put together, using plenty of good hot glue, and spreading it well on the mortises and tenon ends.

When drawing the frame together with the clamps, care must be taken to get it square.

After the glue is hard enough to remove the clamps, the top and bottom

are put in place. The corners of the top are notched out to fit around

the posts, while the bottom is cut to fit on the inside of the rails and

is held in place by putting screws in at an angle through the bottom

into the rails. The top is also fastened in this way, except that the

screws are run through the rails into the top.

The two vertical pieces are now put in place. Drive nails through the bottom and into these pieces. On the top end use screws driven at an angle. Glue may be used if desired.

The doors are made to match these openings. The corners are mitered and the backs rabbeted to receive the panels. These panels may be made in art glass if so desired.

The horizontal piece for the drawer to rest upon is now put in place and fastened by driving nails through the vertical pieces. The drawer is

made to fit this opening, and it should be lined with velvet to keep the silverware in good condition.

The standards and shelves are put on as shown in the drawing. The mirror is put in a frame, which

is made to fit the back opening and has the corners mitered and the back rabbeted to receive the mirror.

Thoroughly scrape and sandpaper all parts that are visible. The sideboard is now ready to be finished as desired.

|

Detail of the Mission Sideboard

Detail of the Mission Sideboard

Mission Sideboard in Quarter-Sawed Oak

Mission Sideboard in Quarter-Sawed Oak